High Precision Fluidize Pellets Coating & Drying Process Technology

Application & Process : Application & Process :

Prism Fluid Bed Processing involves Pellets and Granules coating and drying of particulate materials. It is ideal for heat sensitive and non heat sensitive products in Pharmaceuticals, Biotech, Nutraceuticals, Cosmetic, Chemicals, Biochemical, Food, Dairy, Confectionery, Agrochemical, Herbals, Ceramics, Detergents and Pharmaceuticals Institutes.

The equipment is use application for following process.

- 1. Aqueous or Solvent based solutions or suspensions

- 2. Enteric Release coatings

- 3. Controlled release coatings.

- 4. Fine particle coatings

- 5. Active layering.

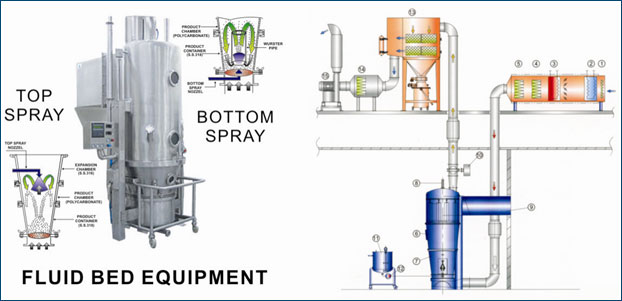

Depending on the application required Prism fluid bed Equipment can be configured into designs as follows :

Fluid Bed Equipment with Wurster Coater Bottom Spray for Granules Coating or Pellet Coating : This process is used to apply a coating to the granules or pellets. This process knows as wurster coater. In this process the spray is done inside a hollow cylinder and from the bottom of this cylinder the pellets are allowed in small quantity to enter the hollow cylindrical tube. Than the particles are passing the bottom spray guns in orderly manner quickly moving upward the tubes to avoid agglomeration. Once they are outside the wurster compartment, they move downward outside the compartment where they dry another layer of coating can be supplied. Since the movement of the particle or pellets inside the wurster chamber totally controlled in ensures uniform.

Salient Features : Salient Features :

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- High Mixing Precision, Short Batch Time, Problem free Cleaning and Residue Free Discharge.

- Single piece construction & Integrated retarding chamber cum filter bag housing

- Wurster Coater- Bottom spraying system for Granules, Pellet & Tablet Coating.

- Different Batch size capacity model available.

- Granulation and Coating system with advance PLC controls system with MMI Touch screen.

- Spraying system with atomized spraying gun and high precise flow peristaltic pump.

- Sampling pot on product container.

- Pneumatic Sealing of Filter Bag and Product container by inflatable silicon rubber tube.

- Inlet Air handler with Air Filter- Micro and HEPA and Heat Exchanger.

- Dual speed mixing impeller for mixing and intensify chopper for granulating.

Optional Features : Optional Features :

- Only Top spray Granulator Model

- Only with Bottom Wurster coater

- Combo model with Granulator and Pellets Coater.

- Flame Proof Electrical.

Safety Features : Safety Features :

- Explosion flap ensures that there no damage to the person operating the machine if there is an explosion inside caused by mixture of air and dust.

- Blower stops if the air pressure in filter bag locking gasket drops below the set value.

|

Fluid Bed Equipment- Processor, Granulator, Pallet Coater & Dryer |

Fluid Bed Equipment- Processor, Granulator, Pallet Coater & Dryer |